A Versatile and Durable Material for Architectural Applications**

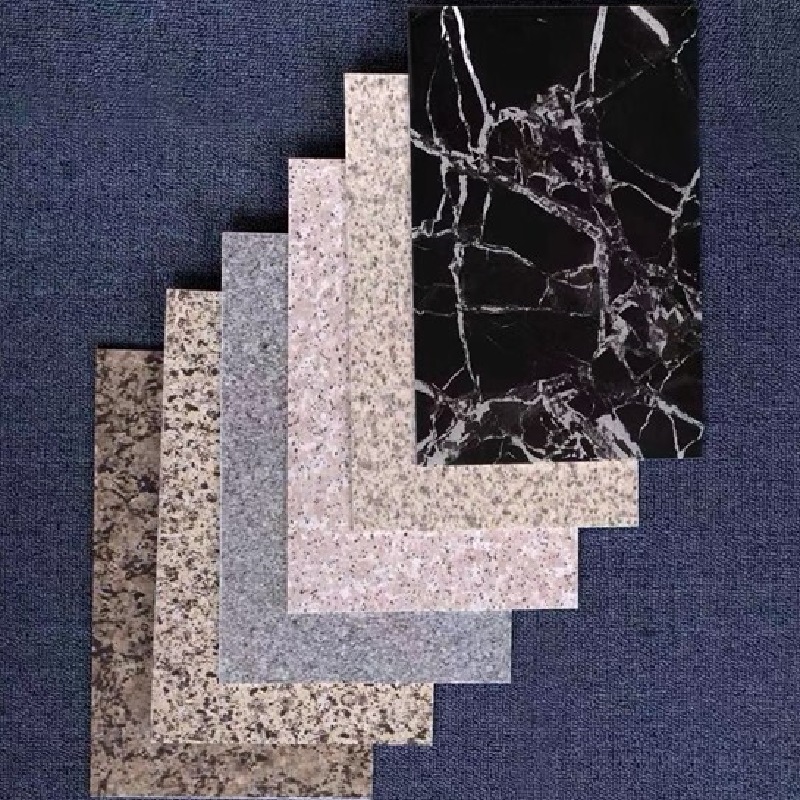

Color Coated Aluminum Coil, known for its high durability and environmental friendliness, is a type of aluminum sheet material with a high weather-resistant HDP (High-Durable Polyester) or PVDF (Polyvinylidene Fluoride) coating prepainted to its surface. This advanced material is widely used in the architectural and decorative industries due to its vibrant color options and outstanding performance.

Alloys:

1000 series, 3000 series, 5000 series, 8000 series.

Parameters

Thickness: 0.1-1.5mm

Width: 600-2000mm (less than 600mm should be slitted)

Coating Type: HDP/PVDF

Key Features

- Corrosion Resistance: The tightly bonded surface oxide layer of Color Coated Aluminum Coil offers strong adhesion, Acid Resistance, Alkali Resistance and Corrosion Resistance

- Uniform and Long-Lasting Color: After this special process, the surface layer can keep no color fading for at least 20 years outdoors, resulting in a lasting and fresh appearance.

- High Rigidity and Strength: The combination of rigidity and hardness allows for free cutting, slitting, arcing, balancing, drilling, joint fixing, and edge compression forming, making it an ideal material for various architectural shapes and designs.

- Outstanding Weather Resistance: PVDF coatings, containing 70% fluoropolymer resin, exhibit exceptional stability against UV rays, moisture, and temperature changes, ensuring that the surface does not chalk or fade for over 20 years outdoors.

- Temperature Tolerance: PVDF coatings can be applied to metal at temperatures above 200°C, and the underlying layer can withstand temperatures up to 150°C. The coating is suitable for long-term use in a temperature range of -60°C to 150°C.

- Low Maintenance and Self-Cleaning: PVDF coatings have a very low surface energy, allowing dust to be cleaned off by rainwater. With a maximum water absorption rate of less than 5% and a minimum friction coefficient of 0.15 to 0.17, they do not adhere to dust or oil.

- Strong Adhesion: PVDF coatings exhibit excellent adhesion to metal, plastic, cement, and composite surfaces.

Applications:

Color Coated Aluminum Coil is widely used in various sectors, including:

- Architectural and Decorative Industries: It is utilized in aluminum composite panels, aluminum veneer, aluminum honeycomb panels, interior aluminum panels, aluminum roll-up doors, garage doors, aluminum ceilings, and thermal insulation composite metal panels.

- Building Facades and Curtain Walls: The material adds a touch of color and style to both interior and exterior applications, providing architects and designers with a personalized color palette for walls and ceilings.

- Electronics and Lighting: It is used in the manufacturing of electronic product casings, computer cases, lights, and furnitures.

- Furniture: The material’s lightweight and durable nature makes it ideal for creating contemporary furniture designs.

1/1